Structural repair precision is paramount in auto collision repair, ensuring vehicles return to pre-accident condition. Professionals use advanced tools like laser scanners and CAD software for accurate measurements, enabling meticulous adjustments and adherence to industry standards. Various measurement techniques, from manual to digital, ensure precise dimensions of damaged components. Detailed documentation and record-keeping, aided by digital platforms and before-and-after photos, are vital for maintaining consistent quality, standard compliance, and client trust across all repair types.

In the realm of construction, ensuring structural integrity through precise repairs is paramount. This article delves into the intricate process of measuring and documenting structural repair precision—a vital aspect of maintaining safe and sustainable built environments. We explore foundational concepts, the latest measurement techniques, and best practices in documentation to ensure repairs meet high standards. By understanding these methods, professionals can confidently navigate complex repairs, fostering longevity and safety for all structures.

- Understanding Structural Repair Precision: The Basics

- Measurement Techniques Employed in Assessing Precision

- Documentation and Record-Keeping Practices for Structural Repairs

Understanding Structural Repair Precision: The Basics

Structural repair precision is a critical aspect of ensuring that vehicles return to their pre-accident condition. It involves meticulous measurements and adjustments to restore the structural integrity and aesthetic appeal of damaged cars. In a car body shop or auto collision center, precise repair techniques are employed to handle various components, from frame straightening to panel replacement.

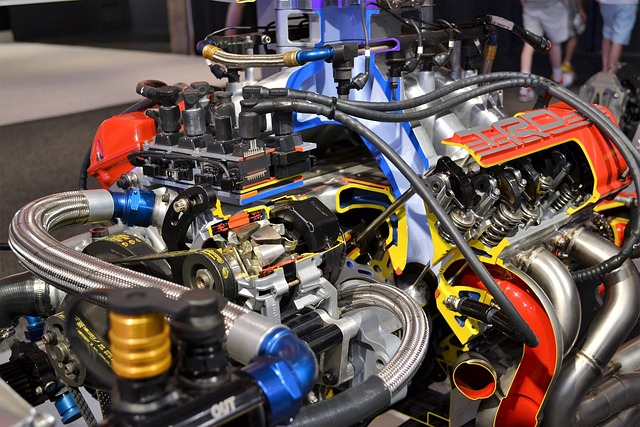

Auto collision repair professionals utilize advanced tools and equipment, such as laser scanners and computer-aided design (CAD) software, to capture accurate measurements of the vehicle’s damaged areas. These digital solutions enable them to compare pre- and post-repair data, ensuring that every adjustment is precise and aligned with industry standards. This level of detail is vital in achieving not just structural repair precision but also maintaining the overall quality and safety of the automobile.

Measurement Techniques Employed in Assessing Precision

In assessing structural repair precision, various measurement techniques are employed to ensure accuracy and adherence to industry standards. These methods range from traditional manual measurements using calipers and rulers to advanced digital tools like 3D scanners and total stations. For instance, in an automotive collision repair setting, a vehicle body shop utilizes laser measuring devices that capture precise dimensions of damaged components before and after repairs.

Auto body painting specialists often leverage these techniques to verify the exactness of panel alignment, gap measurements, and surface contours. By combining these measurement approaches, structural repair precision is meticulously documented, providing a clear picture of the restoration process’ effectiveness. This detailed data not only aids in quality control but also enables continuous improvement in automotive collision repair practices.

Documentation and Record-Keeping Practices for Structural Repairs

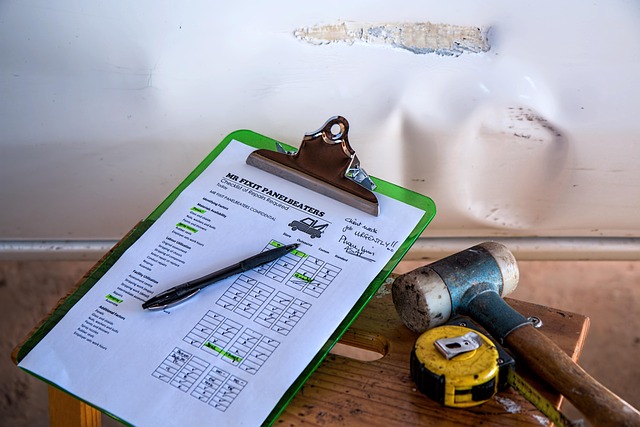

In the realm of structural repairs, meticulous documentation and record-keeping are paramount to ensuring precision and quality. As each repair project is unique, with varying degrees of damage and specific requirements, a comprehensive system is necessary to capture all relevant details. This includes recording initial assessments, detailed descriptions of the repair process, and final outcomes. For instance, in vehicle bodywork repairs, documenting panel replacement or frame straightening involves precise measurements, visual records, and noting the use of specific tools and techniques.

Effective practices involve utilizing digital platforms for easy access and storage. Detailed reports, including before-and-after photographs, can capture subtle changes, ensuring a clear audit trail. Moreover, record-keeping plays a vital role in comparing future repairs, facilitating quality control, and fostering trust among clients. This is equally applicable to auto glass repair and vehicle paint repair, where precision documentation allows for consistent standards and ensures customer satisfaction.

Structural repair precision is a multifaceted concept that demands meticulous measurement and documentation. By employing advanced techniques and adhering to robust record-keeping practices, professionals ensure the integrity and longevity of repairs. Understanding these methods is key to maintaining high standards in the industry, fostering safety, and preserving the structural soundness of buildings for years to come. This article has explored the basics, measurement techniques, and documentation practices, providing valuable insights into the critical domain of structural repair precision.